Innovative Reliable Energy Pioneer

———————————————————— Partnership OEM/ODM ————————————————————

Partnership OEM/ODM

Industrial & Commercial ESS

Residential ESS

Solar-Storage-Mobility Solution

Who we are

FLYFINE ENERGY

Flyfine Digital Energy Co., Ltd. is a fast-growing high-tech enterprise specializing in the research, development, production and sales of products related to residential energy solutions and commercial energy solutions. Our company specializes in the R&D and design of lithium phosphate batteries and solar inverters, providing cutting-edge energy solutions and intelligent energy management services for customers worldwide. As a trustworthy integrated solar energy supplier with 15 years’ rich industry experience and independent R&D capability, Flyfine mainly engages in OEM ODM SKD cooperation with famous overseas brands, and has always been at the forefront of the industry in terms of product R&D and technology reserve. Our products comply with strict international standards, such as UL/CE/IEC/IS09001/14001/Saber etc…..

We aim to being a global energy partner for our customers, create value and benefit everyone, making reliable affordable clean green energy.

Renewable Energy

No Black Out, No Electricity Bill

2+

Two production bases, including lithium battery and solar inverter production workshops, have introduced advanced automated production equipment to guarantee high-capacity output.

150+

The Flyfine workshop has over 150 employees and multiple automated production lines, which can meet large-scale order production and ensure on-time delivery.

R&D Team

Flyfine’s R&D team is composed of 60 professional engineers. We can provide unique customized solutions from software to hardware systems according to your needs to solve your evolving market needs.

Production Capacities

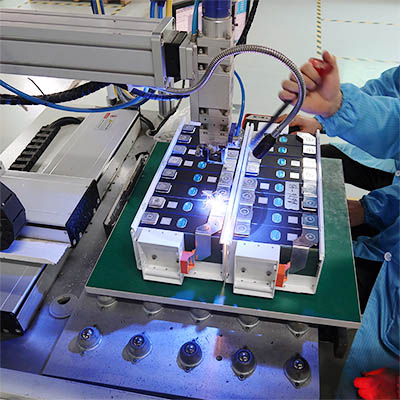

The workshop’s productivity is higher than the industry average for introducing automated production equipment. The current production capacity of lithium batteries has reached 5MW.

>99%

To improve the pass rate of products in the production process, Flyfine has introduced a large number of automated production equipment, such as automatic SMT placement machines, automatic plug-in machines, welding AOI, energy storage ATE testing machines, etc., reducing many defective products and later rework costs.

100,000 GMP

While strictly demanding high-quality products, flyfine also attaches great importance to the environmental requirements of production and has established multiple 100,000-level dust-free production workshops to prevent high-precision parts from being contaminated during the production process and ensure product reliability.

MAIN BUSINESS

Residential Energy Storage System Solution

FLYFINE provides residential energy storage solutions for home users, including energy storage batteries, inverters, photovoltaic panels, photovoltaic brackets, etc.; its main feature is to obtain renewable energy through photovoltaic power generation, which is also the best power for emergency backup power in the event of grid failure. Solution: bringing a more stable power supply system to home users.

MAIN BUSINESS

Commercial Energy Storage System Solution

FLYFINE provides commercial users with customized industrial and commercial energy storage solutions, including photovoltaic panels, photovoltaic brackets, energy storage battery clusters, energy storage converters, energy management systems, etc.; the main feature is to realize power generation through the interactive use of solar energy and grid energy. It balances and optimizes the supply and demand between the power grid, batteries, and loads. It brings a safe, efficient, and flexible experience in peak and valley power, distribution network capacity, and electricity safety for merchants.

MAIN BUSINESS

PV Energy Storage Charging Station Solution

FLYFINE can also provide photovoltaic energy storage charging station solutions, including photovoltaic components, energy storage battery systems, current transformers, integrated EV charging stations, etc.; its main feature is to support high-voltage and high-power setting functions through the interactive use of solar energy and grid energy. ; Improve the charging efficiency of each electric vehicle and increase charging station revenue.

Partnership

Join flyfine global partner channels for better supports.VIP internal professional training, service support, and guidance. Order now and pay later supports (credit up to 90 days). Strategic co-marketing supports price advantage supports etc….

ODM&OEM

Flyfine mainly focus on OEM /ODM. Our R&D team supports software and hardware customization, introduces advanced intelligent equipment and constantly innovates and iterates to make product performance more competitive.Strictly in accordance with international standards for pre-production, in-production and post-production inspection.100% aging test before loading and accept third-party shipment inspection.

SKD Service

Flyfine work with various manufacturers worldwide for Skd services. With our SKD, We provide you high quality standards battery modules with clear and professional product assembly guidelines .Our Battery solutions Production capacity up to 5MW per day while solar inverters capacity up to 4GW per month. Our production capacity is expanding in 2024.

COMPANY CULTURE

Our Mission

Create value for customers and benefit everyone, making reliable affordable energy

Our Vision

To be a global leading and honored provider of green energy

Our Brand Value Concept

Innovation, partnership

Contact flyfine team now

Contact us

Any questions you may have will be promptly answered by our team of qualified specialists.

Sales@flyfinetech.com

+86 15018413606

Appointment

Get a quote now

R&D

Our R&D team can help you with the analyse and design of your desired battery, or energy storage system.

Cell Matching

As part of quality control, each cell is measured and segregated into categories according to their capacity levels.

Terminal Connection

Tab to terminal connections, internal terminal connections, tab welding, seam welding, fill port welding, short circuit protection, laser marking.

Assembly

The assembly process is an important mechanism in assuring the optimized performance of a battery.

BMS Testing

Battery Management System, supporting Bluetooth, communication, or remote control.

Aging & Testing

To ensure the integrity and quality of welded or sealed housing assemblies our Aging Test division has considerable experience in testing systems.